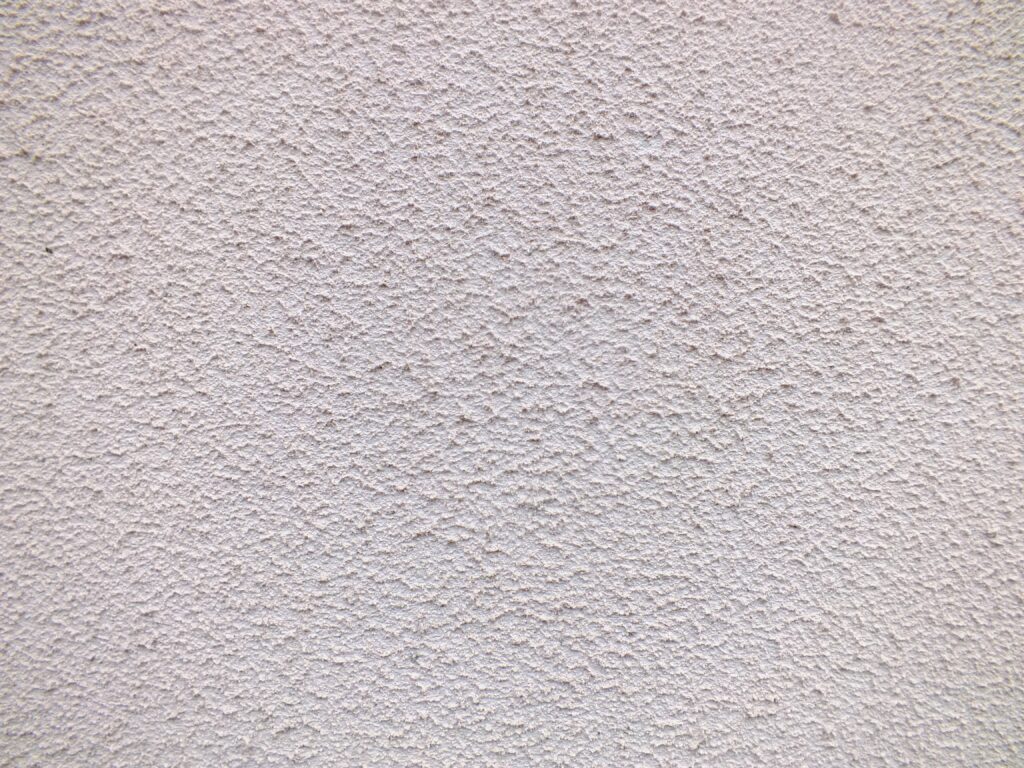

Plastering is an essential part of building and construction that involves applying a mixture of cement, sand, and water to walls, ceilings, and other surfaces to create a smooth and even finish. It not only improves the aesthetics of a building but also enhances its durability and resistance to damage.

However, achieving a flawless plaster finish is not just about applying the right technique and tools; it also requires using the right sand. Let’s discover the importance of using high-quality sand in achieving smooth and flawless plaster finishes, and why it is important to source sand supplies from a reputable supplier.

The role of sand in plastering

First off, what are types of sand used in plastering?

Sand is an integral part of the plastering mixture, and different types of sand are used depending on the specific requirements of the project. The most commonly used sand types in plastering are sharp sand, soft sand, and building sand. Sharp or coarse sand is used for a rougher finish, while soft sand is used for a smoother finish. Building sand is a blend of the two, used for a medium texture.

Using the right quality of sand to create the right consistency for plaster

Sand helps to create the right consistency for the plastering mixture. It acts as a filler, giving the plaster the necessary body and volume, while also providing the required workability for application. The right consistency ensures that the plaster adheres to the surface evenly and smoothly.

The quality of sand used in plastering can significantly affect the resulting consistency of your plaster batch. Sand must be clean and free from clay, silt, dust, and organic matter. The presence of clay can significantly increase shrinkage-induced stress and may lead to deep and wide cracks in the plaster.

Low-quality sand can contain impurities, inconsistent grain size, and poor bonding properties, leading to a poor finish that is prone to cracking, peeling, and discoloration. Using impure sand affects the formation of proper bonds between the cement and sand. Poor bonds usually translate to structures that aren’t as sturdy and strong as they would be if the right type of sand was used.

What are the dangers of using low-quality sand?

- Impurities that can cause surface flaws and discoloration – Low-quality sand may contain impurities such as clay, silt, and organic matter that can cause surface flaws and discoloration, affecting the aesthetics of the finished plaster.

- Inconsistent grain size that can lead to an uneven finish – Inconsistent grain size can lead to an uneven finish, with some areas appearing rough and others too smooth. This can be caused by the use of different types of sand or sand that has not been sieved correctly.

- Poor bonding properties that can result in cracking or peeling – Poor bonding properties of low-quality sand can result in cracking or peeling of the plaster, reducing its durability and making it susceptible to water damage.

What are the benefits of using high-quality plasterer sand in building and construction?

Consistency in grain size and composition

High-quality plasterer sand has consistent grain size and composition, ensuring a smooth and even finish. The consistency in grain size and composition makes it easier to mix and apply, resulting in a plaster that is both visually appealing and durable. When the grain size is consistent, it is easier to control the thickness and texture of the plaster, which leads to a more consistent and even finish.

Improved bonding properties for a strong and durable finish

High-quality plasterer sand has improved bonding properties that result in a strong and durable finish. The sand particles are evenly distributed and bonded together, providing a solid foundation for the plaster to adhere to. This reduces the risk of cracking, peeling, and water damage, which can lead to costly repairs in the future. The improved bonding properties also make the plaster more resistant to impact and abrasion, which adds to its durability.

Enhanced appearance with minimal surface flaws

Using high-quality plasterer sand can result in a plaster that is free of surface flaws and discoloration, giving it a clean and professional appearance. Low-quality sand often contains impurities that can cause surface flaws and discoloration, which can be difficult to repair. High-quality sand, on the other hand, is free of these impurities and results in a smooth and flawless finish. The enhanced appearance not only adds to the aesthetic value of the structure but also improves its market value.

Choosing and researching the right sand supplier for your needs

It is important to research the reputation of different sand supplies to ensure that you are getting high-quality plaster sand and washed sand. Look for reviews and recommendations from other builders and construction professionals; better yet, ring around and discuss your needs and requirements with a number of sand suppliers before making your final decision.

CRI Sands are a leading provider of screened plasterer sand in Perth, with a focus on top-quality products and sustainable operations. Get in touch today to buy quality sand, and any other building and construction raw materials that you need for your project.